White Fields Immobilien GmbH

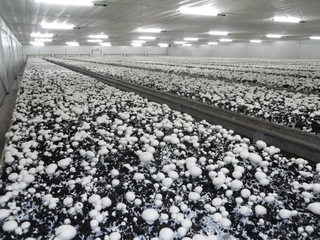

Following intensive preparation 2009 saw the construction of a new

mushroom farm according to a completely new concept. The five owners had

decided to set up a farm applying new techniques and innovations used for

growing and harvesting. The focus here was on a number of aspects including

improving the picking performance, increasing the productivity of the

compost and energy efficient growing practice.

It is common knowledge that the highest picking performance is obtained

from an upper bed with plenty of room. This knowledge was used and

translated into an idea of creating a bed with a single layer and without any

obstructions to picking.

At the farm run by one of the five owners a growing room was transformed

according to this concept. Trials were performed for several years to investigate

matters such as the best distribution of air, compost management in the

bed, the right picking equipment to use and the filling weight of the compost

in relation to the quality.

Technical installation:

A heat pump was installed at the farm. This pump supplies the cooling

required on the farm, while the heat that is released is also used on the farm.

Any surplus heat is extracted using a condenser. In cold periods, when heat

production is insufficient to meet the demand, a steam boiler and a heat

exchanger are used to introduce additional warmth.

To create the best air distribution pattern for the mushrooms the way air

is distributed has been modified. A cloth, which acts as a plenum duct,

is attached to the ceiling. This distributes air through the cloth at low speed

in a homogenous pattern over the entire surface of the beds.

Innovation:

An entirely new technique in mushroom growing is heating and cooling in

the base of the beds. The shelving in the beds incorporates plates which water

flows through. The temperature of this water is regulated by a cooling and

heating circuit. As the energy exchange with the compost is far more direct

the temperature can be managed far more accurately. The compost temperature

fluctuates far less than in conventional farms where the compost temperature is

controlled via the air temperature.

This technique offers a number of advantages:

- effective and accurate control of the compost temperature

- mycelium colonises the casing soil far quicker

- energy saving

- uniform emergence of the mushrooms

- higher productivity per ton of compost

- better spread of pinheads on the beds

- more picking days

The technique can also be applied in existing shelving systems/farms.

Future:

The farm has been built on a site where future expansion has been taken into

account. At the moment the farm numbers seven growing rooms, but there is

space for a total of 28 growing rooms.

The farm has also been configured to allow the harvesting and logistic activities

to be automated. As the mushrooms are grown on single layer beds with the

shelving located in an open space with plenty of room for movement developing

and using picking robots will be far simpler.